Wood floors offer timeless appeal and reliability for any area of your home, but the quality of available wood flooring varies widely. Your flooring supplier will have a range of products in different styles and finishes, and they’ll likely offer you a choice between quarter-sawn and plain-sawn wood floors.

What’s the difference? And how does rotary peelwood flooring compare? Understanding the manufacturing process of hardwood and engineered wood floors, as well as the benefits of each mill type, will help you make the best choice for your home.

What Is Plain Sawn Wood Flooring?

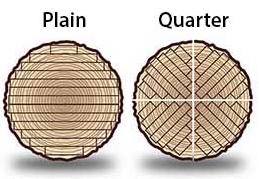

Plain-sawn wood floors, also known as flat-sawn or sliced, feature a looping grain with swirls and curved lines across the surface of the wood. This lumber is milled from a full log, with growth rings angled between 30 and 60 degrees.

Plain-sawn is the most common type of lumber available and is used in a wide range of wood floors, from standard to economical options in various brands, species, and finishes. The benefits of this flooring include its easy availability, natural appearance, and affordable price.

What Is Quarter Sawn Lumber?

Quarter-sawn wood floors are considered premium products. Experts agree that the milling process used to produce quarter-sawn floors creates a stronger, more uniform product with a lower risk of shrinking or swelling. Some also believe quarter-sawn wood better accepts stains and paints, leading to a more durable finish.

To create quarter-sawn lumber, sawmills use quartered logs, resulting in straighter grain patterns that are displayed at angles between 60 and 90 degrees. Quarter-sawn wood flooring is often available in longer lengths as well.

The manufacturing of quarter-sawn flooring requires skilled craftsmanship and results in higher waste levels. As a result, you can expect to pay a premium price for quarter-sawn wood flooring, and lead times from suppliers may be longer.

What About Rotary Peel Flooring?

Rotary-peeled engineered wood floors are typically the most affordable option available. In this process, manufacturers first prepare the log and then use a wood lathe to peel off layers in long strips, similar to unrolling a paper towel.

This method greatly reduces wood waste but results in the weakest grain structure compared to the other milling types. While the finish and appearance are similar to plain-sawn wood, rotary peel flooring may show more variation across different brands.

Comparing the Different Types

Choose the hardwood or engineered wood floor that best fits your home’s décor, budget, and lifestyle. Quarter-sawn wood floors are the most expensive but are known for their durability and consistent grain pattern, making them a long-lasting option.

Plain-sawn wood floors offer high quality at a mid-range price. Their lifespan depends on the thickness of the flooring, but they generally have an average durability. Rotary peel flooring is a cost-effective and visually appealing choice, popular among environmentally conscious consumers, though it doesn’t last as long as the other types.

Quarter-sawn, rotary peel, and plain-sawn wood floors all deliver a beautiful finish to any room. Contact your flooring supplier today to learn more about each type, compare prices, and check availability.